00318 Fc61831291a35229ea5e67ab507c8cf

321

Optimizing Defect Levels and Losses from Gage Errors

Guard Banding

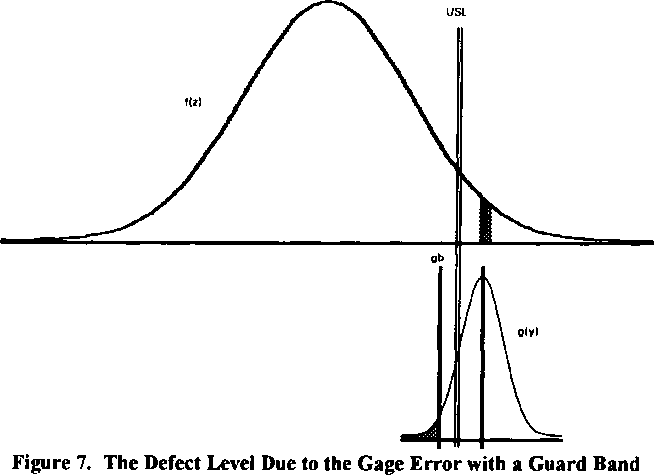

The risk of passing reject units, Figurę 3, is of great concem in finał test applications where all of the product that is passed by the gage is shipped to the customer or sent on to another process step that will add substantial cost to the product. Because of this, many manufacturers impose guard bands on these gages to help minimize the level of defects that are passed on as good product. Figurę 7 shows the improved effect of adding a guard band. There would obviously be a reduction in the defect level; however, the price paid is the potential increase in gage losses.

How are guard bands for test system selected? Several methods are utilized in industry to determine guard bands such as the "best guess" system. The "best guess" system is an iterative approach to guard banding. As long as there are no known defects sent to the customer, the guard band remains the same. However, when the customer retums a defective unit, the guard bands are tightened. This often works fairly well. However, there are three disadvantages to this method. One disadvantage is that it may take a very long

Added.

Wyszukiwarka

Podobne podstrony:

00322 ?b73d4dcbb3956a7a53bceacac34fb9 Optimizing Defect Levels and Losses from Gage Errors 325 Figu

00312 ?50bbf6d416fbf0edb061aff9ba2fbc 315 Optimizing Defect Levels and Losses from Gage Errors fina

00314 ?f49248905805fa4cf0d5be042fd4c1 317 Optimizing Defect Levels and Losses from Gage Errors Figu

00316 ?09c0d2f3a2243d1d46b1f997b3d3cf 319 Optimizing Defect Levels and Losses from Gage Errors Figu

00320 ?5cd1011755558fd005661a9b3cd8ed 323 Optimizing Defect Levels and Losses from Gage Errors Defe

00324 ?4f0003b2ed2810dd76bb30abe464e6 327 Optimizing Defect Levels and Losses from Gage Errors goal

00326 A9b69718dd18cd338e0f0700b7c79c2 329 Optimizing Defect Levels and Losses from Gage Errors + f(

00328 ?80eb3e1366a39705d7b77d62f12780 331 Optimizing Defect Levels and Losses from Gage Errors ao P

00330 r8ad54f747f0f287dd69fb4ed228e35 333 Optimizing Defect Levels and Losses from Gage Errors The

00332 ?133d2464eb28601d2d991683b45647 335 Optimizing Defect Levels and Losses from Gage Errors on t

00334 ?b2793f238bc36b5f1c29c11f214359 Optimizing Defect Levels and Losses from Gage Errors 337 Resp

00336 ?e7e8dcfe0a23e46d4a41cf7d1feb53 Optimizing Defect Levels and Losses from Gage Errors 339 zao

00338 ?79650d4af41fcdcb3a1354afe938a8 Optimizing Defect Levels and Losses from Gage Errors 341 di =

00340 Vbfa1728c6ca8c65c355df31b8a4ed5 343 Optimizing Defect Levels and Losses from Gage Errors Grub

00310 Ad65eb5323f68600e39f63d1a31de2f 16Optimizing Defect Levels and Losses from Gage Errors Daniel

10087 P1060313 JANUSZ OSTOJA -ZAGORSKI quaniii) was important and considered as neoe&sary. bot h

crosa-sectional araes by 10 and 50%, and, finally, two struc-tural ełements in the mkłdle of the tel

158 A. Rusińska ... MATERIAŁ AND METHODS Field studies were conducted in the period of May--June 200

więcej podobnych podstron